IP25 next Level

SICAM

How ideas become concrete products

Trends repeat themselves and are already outdated by the time they are ready for market. But what is still possible in decor printing? A legitimate question that Interprint asked itself. The IP25 OpenHouse in May marked the beginning of a rethink. Interprint embarked on a revolutionary journey of ideas. The first highlights were on display at SICAM in Pordenone, Italy. And that's not all: Interprint also impressed trade fair visitors with its MODUS thermoplastic films and its sustainability efforts.

Artificial intelligence and materials with a life of their own

“What happens when decor design no longer waits for the next trend, but creates new perspectives itself?” With this question, Interprint invited visitors to the IP25 OpenHouse in May to join in the discussion: Based on the five key themes of Tech, Society, Material, Nature and Vision, the aim was to explore what is possible. Over the past few months, designers have used this experimental Surface Matrix to develop new decors that stimulate active perception. Designs that evoke an emotional response. And surfaces that only come to life through interaction and attention. Designs that go far beyond fleeting trends.

For the first possible stone designs presented at SICAM, onformative, the studio for digital art and design, contributed creative prompts and algorithms. Artificial intelligence enables endless new variety. Surprising materiality. Structures that appear to have grown, but never existed. Digital, but with a lot of soul.

The design process is often dominated by the urge for perfection and control. But materials have a life of their own. Unpredictable. Exciting. Material artist Veronika Moos therefore shows how materials help shape their own look. Her focus for the SICAM decors was on dyed wood panels as independent design carriers.

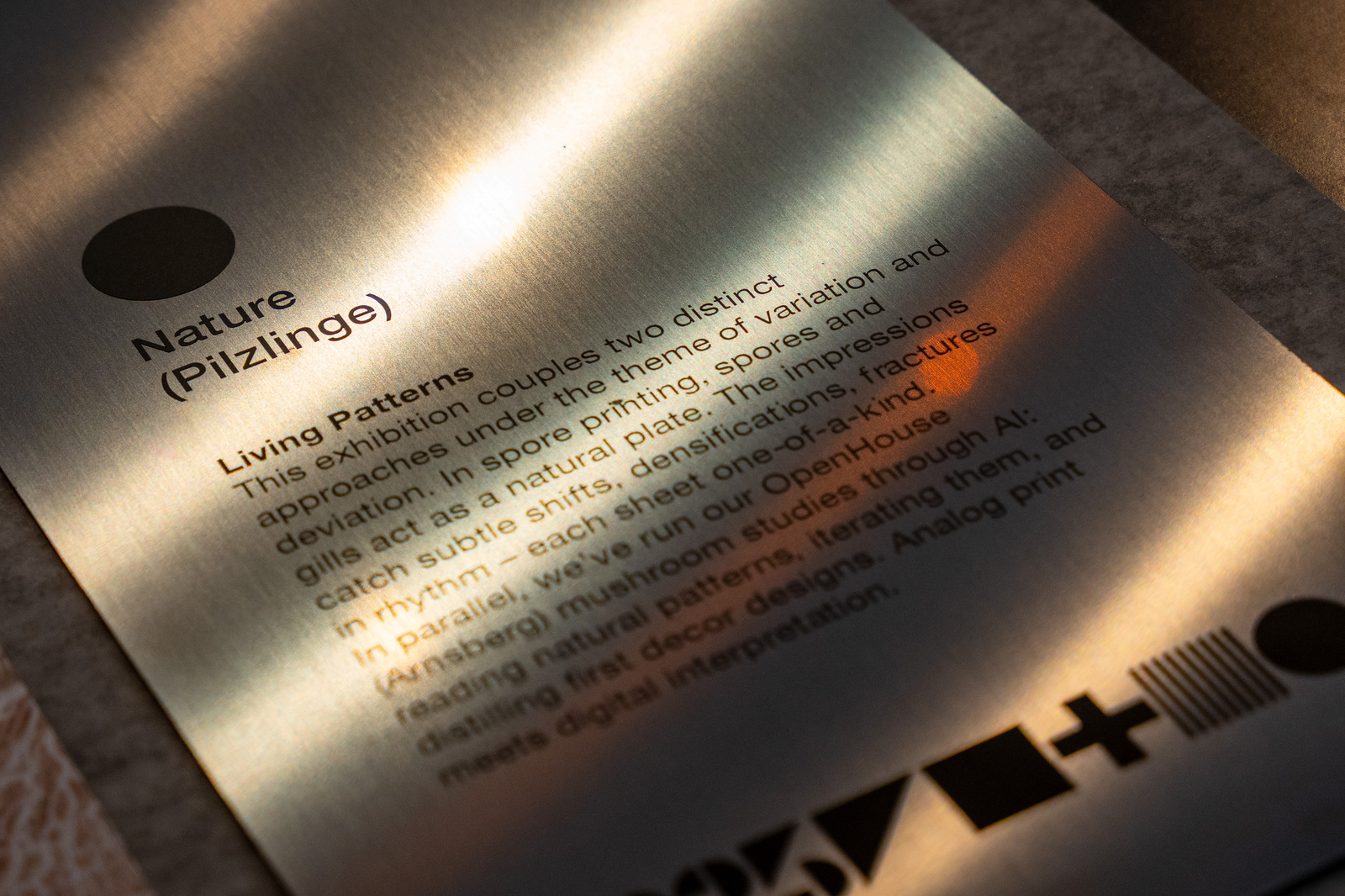

A mushroom as a creative catalyst and waste as a resource

Nature does not always design straight lines. It follows organic, complex patterns. At the OpenHouse event, the first decor studies were presented in collaboration with the Cologne-based mushroom farm Pilzling. Mushroom structures combined with digital methods. At SICAM, Interprint presented the first AI decors created in this way. Mushrooms as natural printing plates – an appealing approach for sustainable, future-proof designs.

But looking to the future also requires looking at sustainability. What happens when waste is viewed as a resource? Together with the Lisbon-based studio By the End of May, Interprint examined local production and recycling processes. Acoustic panels and carrier boards are made from the company's own paper waste. The prototypes at SICAM prove that a cycle is complete when something new is created from something old that truly lasts. A sustainable design approach.

Aesthetics of the past for future innovations

Anyone who wants to create relevant, lasting designs should look to the values, forms, and aesthetics of the past. And combine them with modern approaches. Through discussions with customers and experts, Interprint has identified important design trends: calm, irregular, real and responsive. These form the basis for new surfaces that come to life through interaction.

MODUS Film – new possibilities with thermoplastic films

At SICAM, Interprint demonstrated that it has not lost sight of technological innovation in all its design experiments with the thermoplastic films of the MODUS Film line. Thanks to a specially developed color-receptive layer, Interprint can print on both PP and PVC with water-based inks – even in Industrial Digital Printing. MODUS Print – Analog decors Orwill Oak and Balveny Oak are the first two designs that Interprint can print not only on paper but also on PVC film with a roll width of 1,450 mm as a matching product combination.

MODUS Finish – Exelle Synchro expands the product group with a high-quality optical pore. MODUS Finish – PET was designed for front applications (e.g., lacquer laminates). And MODUS Finish Plus – r-PET combines thermoplastic films with genuine sustainability. With a recycled content of 30%, this MODUS product contributes significantly to CO₂ reduction.

Sustainable paper selection

For more than 15 years, Interprint has been committed to developing sustainable paper solutions. With success. The argument of higher paper prices has long since lost its significance. Interprint's aim is to further increase customer interest through its pioneering role and to reduce the prices of sustainable papers in the medium term.

The 2nd Harvest Paper – a tree-free paper with significantly reduced CO₂ emissions – has already triggered a rethink in the market. The fibers for this paper come from harvest residues of fast-growing plants that are harvested repeatedly within a year. The excess material would otherwise be burned or dumped.

Recycling Decor Paper made in Germany were presented for the first time by Felix Schöller at SICAM with creative Interprint designs. Despite its more inhomogeneous texture, Interprint has successfully printed an attractive decor onto Silphie Fiber Paper. This is also a promising option for customers. Cradle to Cradle Paper, which is produced in a CO₂-neutral manner, also meets strict sustainability criteria through the use of recycled fibers, renewable energy, and other factors. Interprint has already successfully tested this paper and has also added it to its portfolio since SICAM. For Interprint, the status quo in terms of sustainability is not a reason to rest on its laurels, but rather an incentive to seek further solutions for the industry.

The Future of Decor Printing

The IP25 journey continues – with creativity, curiosity and technological expertise. Looking ahead to a promising future for the industry. Free from trend constraints. Open to new ideas. And ready for a wide range of possibilities. Sustainable in every aspect. interprint.com/ip25